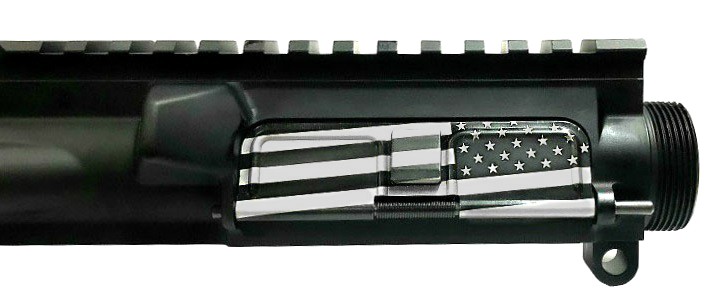

Nickel Teflon Complete Upper Receiver (M4 Flat Top)

Electroless Nickel Teflon has continually proven to outperform traditional Anodizing and Phosphate coatings by leaps and bounds! The increased reliability, corrosion resistance and ease of maintenance make this upgrade a no-brainer.

RUN IT LONGER AND HARDER. Lubrication optional. If you decide to use lube you won't notice when it dries up. The natural lubricity of Nickel Teflon has a much lower coefficient of friction than phosphate treated steel with lube applied.

LUBRICITY & WEAR RESISTANCE. Lubricity plays an essential role in optimizing wear resistance and longevity. Nickel Teflon has a .05 Coefficient Of Friction (COF), creating a surface more slick than Anodizing, Hard Chrome or even Nickel Boron.

LONGEVITY. Has a Hardness of Rockwell 54. Guaranteed not to peal or flake

EASE OF MAINTENANCE. No scrubbing required. Carbon fouling literally just wipes off with a rag.

CORROSION RESISTANCE. We apply a proprietary Electroless Nickel substrate with a higher than average phosphorus content, giving the coating a barrier that's practically impenetrable by corrosion.

Note: Nickel Teflon will buff out and produce polished spots on contact/friction points. When using a clamshell type receiver block, the contact points may cause slight discoloring on the exterior of the receiver. This of course is strictly cosmetic. However, if you're trying to avoid discoloration then we recommend using a (pin type) receiver vise. BCG not included.

- Forged & Machined by Cerro Forge (Key Hole)

- Machined From Mil-Spec 7075 T6 Forging

- M4 Feed Ramps

- Proprietary Electroless Nickel Teflon Finish

- 100% increase in corrosion resistance compared to MIL-A-8625 hard coat anodizing

- 240% increase in lubricity compared to MIL-A-8625 hard coat anodizing

- 160% increase in lubricity over hard chrome